Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

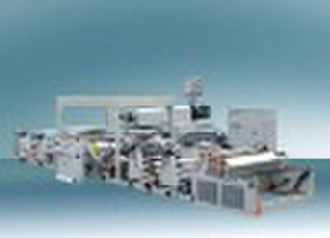

SJFM800-1800 High-speed Extrusion Film Laminating

Zhixin Li

Contact person

Basic Information

SJFM800-1800 High-speed Extrusion Film Laminating Machine Characteristics This series of products are made by compounding fluid paper, plastic film, woven cloth or aluminum foil into double layer, three layer or multi-layer new materials, which are used for packaging the products like cement, chemicals, forage, food, medicine, adhesive tape cloth, plastic coating paper sups and fast food boxes, etc. 1. PLC man-machine interface with central control, integrally designed with machine and electricity system. 2. Its support with a double feeder, high effective corona unit and automatic hydraulic exchanging filter screen are the first invention of its kind at home, which can increase the strength to strip the products. Main Technical Variables typeSJFM-800SJFM-1100SJFM-1300SJFM-1600SJFM-1800lengh of die lip900mm1200mm1400mm1800mm2000mmwidth of finished product400-700mm500-1000mm600-1250mm800-1500mm900-1700mmmax compounding speed100-150m/min100m150m/min100-150m/min100-150m/min100-150m/minthickness of shower film0.01-0.1mm0.01-0.1mm0.01-0.1mm0.01-0.1mm0.01-0.1mmL/D ratio for screwΦ80mmx30Φ95mmx30Φ105mmx30Φ120mmx32Φ140mmx32max. diameter for roll unwinding and rewindingΦ1200mmΦ1200mmΦ1200mmΦ1200mmΦ1200mmoverall size9600x6000x3200mm9600x7000x3200mm9600x8000x3200mm9600x9000x3200mm9600x1200x3200mmpower60kw70kw80kw100kw130kwcompounding/ mirror cool rollΦ510mmΦ510mmΦ510mmΦ510mmΦ510mm applicable for base materialBOPP, BOPET, BOPA, CPP, PAPER, Aliminum foil

Delivery terms and packaging

Port: Shanghai, Ningbo

Payment term

Letter of credit

Telegraphic transfer

-

Payment Methods

We accept: